THE CORONAVIRUS has had a devastating effect on the health of the global economy. The decline in economic activity will generate a synchronised global slowdown.

Hopefully, government action will limit the fallout, and we could see a bounce back later in the year. However, the crisis will have more permanent ramifications. One of them will be on global supply chains.

The rise of globalisation, in the aftermath of the collapse of the Soviet Union, had a major impact on manufacturing and trade. The late 1980s were cathartic for the United States. While Washington was trying to outspend the Soviets in defence, the private sector was trying to regain competitiveness against Europe and Japan.

The late 1960s and 1970s had been painful for the pride of US industry, as it saw German and Japan manufacturers rise out of the ashes of World War II and move into the competitive forefront. American automobile manufacturers could not compete in quality and price, and they saw their market share evaporate.

Businesses and academics began studying and copying their rivals techniques, particularly those of Japan. They rediscovered the ideas of W. Edward Deming, and his theory of total quality management, or TQM.

Deming was an American consultant who had worked in Japan after the war. His ideas had been embraced by Japanese manufacturers, such as Toyota, and had been instrumental in rebuilding their products. They also discovered the important of ‘just in time’ manufacturing, whereby companies would work closely with their suppliers to ensure that they would deliver components just as they were needed. Also, known as lean manufacturing, it would reduce the need for costly inventories and reduce working capital.

The reincorporation of China into the global economy in 2001 fit perfectly into the new scheme. Manufacturers flocked there to source cheap components, taking advantage of low labour costs. Advances in computing and transportation also allowed them to tighten their logistic chains and deepen their integration.

Designers would only upload modifications to blueprints, and the new components could be on the next 747. It was a dream come true.

However, the coronavirus showed the flaws of the system. One of the factors that exacerbated the effects of the pandemic was when Beijing decided to act during the Chinese New Year. Although the disease broke out some time during the fourth quarter of 2019, quarantine measures were not put in place until late January 2020, when people were on their New Year’s holidays. Lockdowns and travel restrictions left many workers far from their factories.

As a result, most manufacturers were not able to restart operations for months. This was firmly confirmed with the trade data, which showed exports dropping 17.2 per cent y/y during the first two months of the year. Chinese auto suppliers in key products, such as brakes, windshields and batteries, have become globally dominant.

Without these components, many manufacturers in Japan, Korea, the United States and Europe were forced to shut down. This was not limited to the automobile industry. It was felt across the board. For example, Apple, which depends heavily on Foxconn or Hon Hai for many of its products, suffered huge declines. Yet, this is not the first time this has happened.

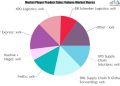

As a result of the prevalence of pandemics in China, many manufacturers are rethinking their supply chains. Some of this was already taking place prior to the outbreak of the coronavirus. Rising Chinese wages, rampant intellectual property theft, trade wars and the growing role of robotics had forced many manufacturers to move some of their operations out of China.

Vietnam and the Philippines were some of the initial winners. However, some manufacturers were starting to bring their operations back to their home markets. Given the prominence of robotics and artificial intelligence in the manufacturing process, labour costs are becoming moot.

At the same time, transportation costs are becoming more prominent. The reshoring of manufacturing operations will benefit countries that are part of the domestic supply chain. For the United States, this means Mexico, as well as the member countries of CAFTA-DR, which are Costa Rica, El Salvador, Guatemala, Honduras, Nicaragua, as well as the Dominican Republic. For Europe, this means Turkey, as well as the Eastern European countries, such as Poland, Czech Republic, Bulgaria and Romania.

The alterations to the global supply chain may have a lasting impact on the Chinese economy, but it may also have an important impact on global inflation. Shortages and problems associated with reorganising supply chains may lead to a rise in prices, which could unexpectedly work their way into higher consumer prices and leave central banks wrong-footed.

The full impact of the coronavirus will have many lasting effects, and one of them may be on the global supply chain.

Dr Walter T. Molano is a managing partner and the head of research at BCP Securities LLC.